What have you been hearing from your customers? Do they think the price of your product is too high or the quality is low? Make sure everyone is on the same page about your problem before you start mapping. Think about this question from the customer’s perspective. What problem are you solving? Looking at the current state map, what are the deficiencies in the process flow? How can you improve future states?

Who is mapping the value stream? It’s important to assign this task to an experienced team who can see the current state map and future state maps from start to finish. Which aspect of the product has the highest business value? Answer that question before you start building your map. What factors should you keep in mind when creating a value stream map? 1. How does your timeline look? What process steps have you mapped out? Is your lead time too long? Are you seeing test failures? Identify any steps in the process that do not add value to the customer. Once you’ve drawn your map, don’t be afraid to iterate. Remember, lean management demands continuous improvement. This is how you’ll be able to shed light on which steps and transitions are wasting time and resources. Base this on your real-world cycle time data. Include flows that don’t match the resource flows, such as sending regular updates to a central management team.Īdd a timeline that shows how long each step takes.

Add arrows of a different color to show which steps must communicate with each other to complete the process. Label each arrow with the resources that must be transferred for the next step to be possible.Īdd information flows. It might help to think of each team as its own step.Īdd the flow of materials between each object. What steps do you take to prepare a single product or feature for the customer? Create a box for each one. When do you start adding value to the raw materials, and when do you hand the finished product off, either to a customer or another business?Īdd objects for each step.

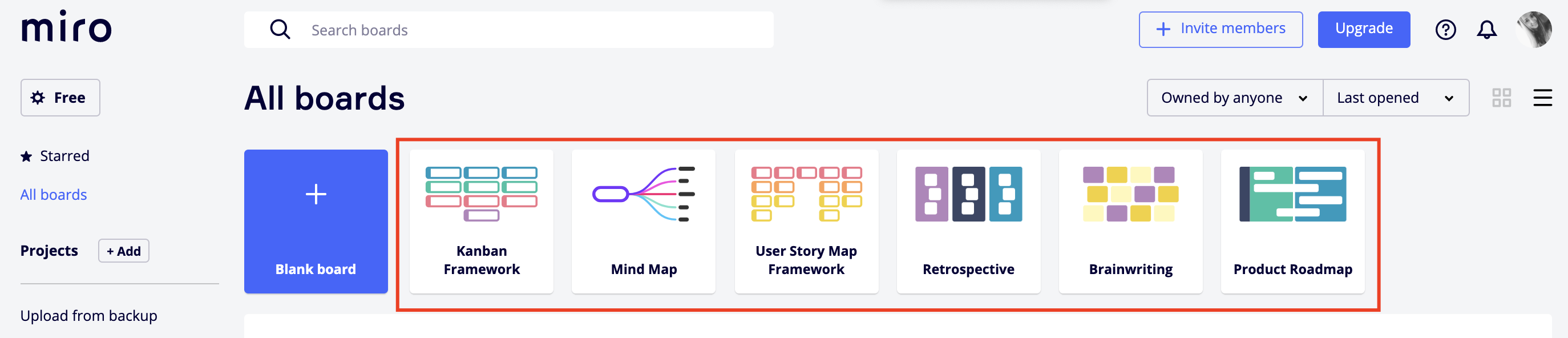

Figure out the start and endpoints of your value stream. Invite your team to collaborate on the template, then follow these steps.ĭetermine your scope. Start by selecting the Value Stream Mapping template on this page. This laser focus maintains your competitive advantage the only way it’s possible to do so sustainably: by producing the most value for your customers in the leanest way possible. The value stream mapping exercise forces you to evaluate whether each step in the process is adding value from the customer’s standpoint. But when there are so many teams and moving parts to think about, that focus can be hard to maintain. Focus on the customerĪt all stages of production, your focus should be on the customer. With value stream mapping, you can reduce downtime from team transitions, making a Toyota-style lean strategy more feasible. Value stream analysis allows you to overcome this obstacle by clarifying which handoffs are causing waste and why. That costs your company precious time and resources. If anything falls through the cracks, Team B has to waste time reinventing the wheel. When a project changes hands from Team A to Team B, it’s crucial to make sure all of Team A’s knowledge, experience, tools, and resources go with it. Most of the waste in your production process occurs during handoffs between teams.

Once you’ve identified these gaps, you can brainstorm ideas for fostering communication and knowledge-sharing. Value stream maps make it easy to identify gaps in communication between teams and across functions. Value stream mapping is a critical component of any business strategy. What are the benefits of value stream mapping? With this template, you can pinpoint every obstacle keeping you from a streamlined production process, no matter what industry you’re in. The Miro Value Stream Map template promotes communication and collaboration on better cross-functional processes. To accomplish a just-in-time strategy like Toyota’s, a clear value stream analysis is non-optional. Toyota’s lean strategy minimizes time-to-market, but it relies on continuous improvement. Following their “just-in-time” strategy, the Japanese automaker only delivers enough finished cars to meet demand, which keeps them from losing money on storage and holding patterns. Value stream mapping originated from the lean manufacturing methodology developed by Toyota. The map helps you spot waste, eliminate inefficiencies, and build processes that deliver real value on tight timeframes. What is a value stream map?Ī value stream map is a powerful tool you can use to analyze any process with repeatable steps. With our Value Stream Mapping template, you can create your own map easily. Value stream mapping helps you better understand repeatable processes, allowing you to optimize them accordingly.

0 kommentar(er)

0 kommentar(er)